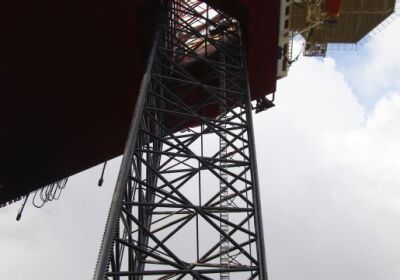

Jacking System Survey

For safe jacking operations

The jacking system is one of the most critical systems onboard a jack-up rig but often proper maintenance is neglected. Inspections help to prevent failures from happening and can identify maintenance related issues.

ModuSpec have recognized jacking systems are often widely neglected in way of proper maintenance. Also, we have identified occurrences of very little information on past failures being properly recorded and insufficient details provided in the maintenance history files.

Therefore, the ModuSpec inspection focusses on the following:

- Inspection and review of all Jacking Motors

- Review of the Motor Brakes Torque and Holding Torque

- Inspection of Climbing Pinion Bearings

- Inspection of Guides, Frame and Pads (Fixed system)

- Inspection face of gear and face of bearing carrier (fixed system)

- Shaft seals

- Shock pads (floating system)

- Inspection of RPD system

- Inspection of Jacking control panels

- Gearbox oil analysis to check for evidence of wear metals and water contamination.

To maintain the most efficient timing ModuSpec will request assistance in preparation by the rig crew, if available, to drain oils. Teams working on each leg simultaneously will greatly speed up the gearbox sump oil inspection process.