Well Control Equipment API Std 53 Compliance

Compliance & Safety

A BOP / Well Control equipment assessment to highlight any items of non-compliance with regards to API Standard 53 prior to operations.

The API Standard 53 compliance assessment can be carried out in parallel a BOP Inspection, and the BOP inspection report will contain two sections:

- Well-Control Equipment Report

- API Standard 53 Compliance report – with non-compliance Findings

The BOP scope will include the following:

- Determination of status of any outstanding recommendations (previous inspections)

- Verification of NDT - MPI inspection records

- Inspection of drape and flex hoses - hose management system

- Inspection and function test of BOP handling system

- Visual inspection annular BOPs - to look for key seating wear

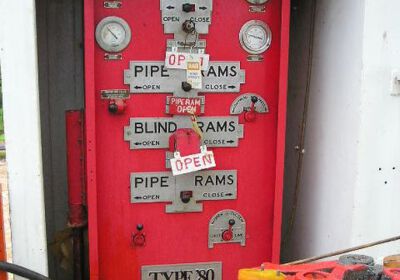

- Visual inspection ram type BOPs - to review dimensional checks on the cavities and the rams

- Inspection of BOP mounted choke and kill valves

- Operator chamber tests - pressure and function testing

- Check for key seating wear

- BOP stack general condition inspection and tests

- Accumulator pre-charge pressures, all systems. API 16D accumulator volume calculations performed/verified by main office.

- Review of BOP controls system plumbing

- Spare parts inventory

- Planned PMS / BOP Logbook

- BOP and related equipment pressure tests

- Choke and kill manifold plus related equipment

- BOPs and control system function tests and drawdown test

- Drift test of BOP stack with attention to the annular BOPs

- Reference documents used - API and applicable regulations